About Us

Contact Info

- G12, 3rd phase, Dubai Industrial City (DIC), Dubai, UAE

- sales@morshedi.co

- Week Days: 09.00 to 18.00

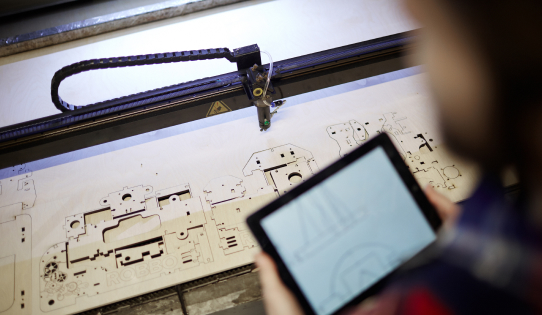

Bevel Sheet Laser Cutting: High-Precision Angled Cuts for Industrial Applications

Bevel sheet laser cutting is a specialized technique that allows for angled and chamfered edges, improving welding precision and structural integrity. This advanced method ensures that metal sheets fit seamlessly together, reducing gaps and enhancing joint strength. In this process, the laser nozzle cuts the cross-section at a precise angle, creating the perfect gap for future welding. At Morshedi, we provide state-of-the-art bevel laser cutting services using the latest technology, catering to industries that require high-precision fabrication solutions.

Why Choose Bevel Sheet Laser Cutting?

Unlike standard laser cutting, bevel cutting enables angled edges, which are particularly beneficial in welding, construction, and industrial assembly. This ensures that components fit together more seamlessly, reducing gaps and weak joints.

Accurate Angled Cuts: Delivers precise, clean bevel edges for flawless assembly.

Enhanced Welding & Fitment: Reduces gaps and improves welding quality.

Faster Production Process: Higher cutting speeds compared to traditional beveling methods.

Versatile Material Processing: Compatible with stainless steel, aluminum, mild steel, and other metal sheets.

Cost-Effective & Minimal Waste: Optimized cutting paths maximize material utilization.

Maximum Cutting Dimensions: Largest processable piece L=12000 * W=1000 * H=400 mm

Machine Table Size: 12000×2000 mm, allowing for larger and more complex parts.

Free Consultation , We can built it.

Mr. Morshedi

CEO & FounderAdvanced Bevel Sheet Laser Cutting in Dubai and Across the UAE

As industries across the UAE continue to demand greater accuracy, efficiency, and customization in metal fabrication, bevel sheet laser cutting in Dubai, UAE has become a pivotal service for achieving superior joint performance and clean assembly.

Morshedi’s specialized approach brings next-generation capabilities to a range of sectors, including oil & gas, infrastructure, marine, and aerospace, by offering exact bevel angles that enhance every aspect of structural and welded joints.

The Importance of Precision in Bevel Sheet Laser Cutting

Precision bevel sheet laser cutting is also about engineering exactness along with the angled edges. Our CNC-guided laser systems facilitate meticulous bevels with regularity and repeatability, even on composite geometries or heavy-gauge materials.

You might be making metal sheets for load-bearing structures or forming seamless weld-ready edges for architectural installations, exactness is a must. Morshedi’s process make sure that all your projects of bevel meet dimensional tolerances and finish expectations.

Tailored Solutions for Unique Project Demands

When clients approach us for a custom bevel sheet laser cutting service, they want for more than standard capability, they seek adaptableness and personalization. At Morshedi, we design each job according to your specific material type, thickness, and bevel angle, ranging from 0° to 45°.

This custom service meaningfully improves fitment for parts that require seamless transitions, minimizing post-processing time and boosting overall fabrication efficiency.

Our ability to manage high volumes while maintaining complicated detail makes us the best partner for both small-batch runs and large-scale production. From thick structural plates to decorative aluminum panels, every order is managed with precision and care.

Accuracy with CNC-Controlled Technology

Leveraging advanced machinery for CNC bevel sheet laser cutting, we bring automation, consistency, and high-speed processing together. Our systems are capable of executing multi-axis bevel cuts with exacting tolerances, producing consistent results across a wide range of metals.

This CNC control enables us to cut complex profiles and chamfers with minimal deviation, good for industries that demand rigorous standards such as automotive, aviation, and shipbuilding.

Specialized Services for Steel and Aluminum

Clients many times bevel sheet steel laser cutting in Dubai when working on structural projects that require strength, integrity, and weld readiness. Morshedi offers supreme expertise in working with mild and stainless steel sheets for high edge quality and clean bevel geometry.

Similarly, for non-ferrous projects, our aluminum bevel sheet laser cutting in UAE service guarantees smooth finishes, reduced heat deformation, and high processing speed. It is very important for industries like transportation and electronics, where accurate aluminum parts are repeatedly used.

Applications of Metal Laser Cutting

Construction & Architecture

Used for building facades, decorative panels, and precision welding.

Shipbuilding & Marine

Essential for curved and angled steel components in ship construction.

Industrial Fabrication

Required for machinery parts and load-bearing structures.

Aerospace & Automotive

Used for lightweight, durable, and high-precision metal parts.

How We Deliver Precision Bevel Cuts

Consultation & Design

Reviewing project specifications and technical requirements.

Material Selection

Choosing the right metal sheet type and thickness for optimal cutting results.

Precision Cutting

Utilizing CNC-controlled laser technology to achieve exact bevel angles.

Quality Control & Inspection

Ensuring every cut meets strict industry standards.

Final Delivery

Providing ready-to-use beveled sheets for fabrication or welding.

Trusted Partner for Bevel Sheet Laser Cutting in Dubai

Looking for high-precision bevel sheet laser cutting services in Dubai? At Morshedi, we offer advanced laser cutting solutions tailored for construction, industrial, and manufacturing clients in the UAE. It includes sheet laser cutting, beam laser cutting, tube laser cutting, and bevel sheet laser cutting. Our localized expertise and advanced machinery ensure high-quality results for projects requiring angled metal sheet cutting.

Get in Touch Today!

We understand that pricing transparency and turnaround time are essential to your operations. That’s why Morshedi offers fast, competitive bevel sheet laser cutting quotes Dubai through a streamlined inquiry process. Simply share your specifications, and our team will provide a detailed quote, turnaround estimate, and material consultation.

Looking for high-precision bevel sheet laser cutting services? Contact Morshedi now for a consultation or a custom quote. Let us help you achieve superior accuracy and efficiency for your next project.

Frequently Askes Questions (FAQs)

1. What is bevel sheet laser cutting?

Bevel sheet laser cutting is a technique used for metal fabricators to cut bevels at various angles on sheet metal. Such a bevel cutting process is best for applications requiring edge preparation or complex welds.

3. Why choose bevel cutting over standard sheet laser cutting?

Bevel sheet laser cutting gives metal fabricators the ability to cut bevels with high precision and minimal post-processing. It offers cleaner edges and is better than old-style straight cuts.

5. What are the different ways to cut a bevel in metal?

Bevel sheet laser cutting enables metal fabricators to cut bevels using methods like mechanical milling, plasma, or bevel cutting with laser. Each method offers different advantages based on precision and material.

7. What are the benefits of laser bevel cutting?

Bevel sheet laser cutting gives a way to cut bevels with minimal waste and superior exactness. Laser bevel cutting supports quicker workflows and improved welding prep with minimal distortion.

2. Why do metal fabricators need to cut bevels?

Bevel sheet laser cutting helps metal fabricators cut bevels for better weld penetration and cleaner joints. Bevel cutting also improves assembly efficacy in structural and industrial applications.

4. What are the common bevel types offered?

Through bevel sheet laser cutting, metal fabricators can cut bevels like V, X, K, and Y shapes. These bevel cutting profiles can help different types of weld prep requirements in fabrication and manufacturing.

6. What is off-table beveling?

Bevel sheet laser cutting may be complemented by off-table beveling when metal fabricators need to cut bevels on parts that don’t fit traditional setups. It is a method that adds flexibility to operations.

8. How do I request a quote or begin my bevel-cut project in UAE?

In order to get started with bevel sheet laser cutting, reach out to Morshedi through our communication channels. Our bevel cutting team will assist with timelines and pricing for your bevel-cut project.