About Us

Contact Info

- G12, 3rd phase, Dubai Industrial City (DIC), Dubai, UAE

- sales@morshedi.co

- Week Days: 09.00 to 18.00

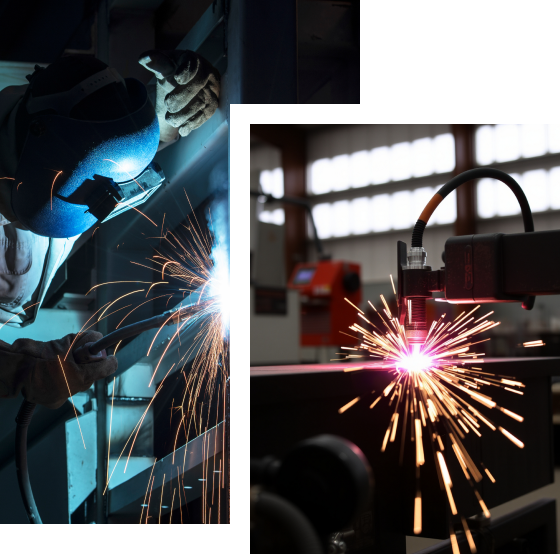

Laser Welding Services in Dubai, UAE – High-Precision Metal Joining for Industrial Applications

Laser welding is a high-precision and efficient welding method used for joining metals with minimal heat distortion. At Morshedi, we offer advanced laser welding services capable of handling I-Beam, U-Profile, L-Profile, T-Profile, Z-Profile, Pipe Profile, Structural Tubes, and Hot & Cold Rolled Profiles with unmatched accuracy. Our state-of-the-art laser welding machines are designed for welding aluminum (AL), mild steel (MS), stainless steel (SS), and galvanized steel (GI), making them ideal for construction, industrial fabrication, and heavy-duty manufacturing.

Why Choose Our Laser Cutting?

High Precision & Accuracy: Achieves clean, smooth, and distortion-free joints.

Strong & Durable Welding: Provides high-strength bonding for industrial applications.

Minimal Heat-Affected Zone (HAZ): Reduces warping and maintains metal integrity.

Versatile Material Compatibility: Works with aluminum, mild steel, stainless steel, galvanized steel, and more.

Fast & Efficient Production: Shortens lead times and improves manufacturing efficiency.

Free Consultation , We can built it.

Mr. Morshedi

CEO & FounderAdvanced Laser Welding for Industrial-Grade Performance

At Morshedi, you will get high-precision metal bonding solutions that can be tailored according to the complex industrial demands. As a trusted provider of laser welding service in Dubai, UAE, our facility supports fabrication shops, contractors, automotive firms, and heavy industries with consistent weld quality, fast turnaround, and unmatched process control.

Our laser welding systems can handle different joint geometries and material combinations with exceptional accuracy. You might be working with round profiles, complex edge joints, or box structures, we bring your specifications to life with lower heat distortion and supreme structural integrity.

Meeting Modern Manufacturing Standards

The manufacturers these days demand more than just functional welds. They require flawless, distortion-free seams that meet international quality and durability standards. Morshedi can help meet these requirements by combining experience with advanced technology.

As one of the most reliable laser welding companies in the region, we apply industry-best practices across all operations. It can be part fixturing to laser beam calibration. You might be producing high-volume parts or limited-batch components, we make sure a clean, consistent weld with each pass.

In high-risk sectors such as aerospace, defense, or medical device manufacturing, even the smallest weld imperfection can lead to failure of the component. That is why Morshedi emphasizes process control, joint cleanliness, and post-weld inspection as part of our standard service.

Custom Solutions for Challenging Applications

Morshedi also specializes in custom laser welding in Dubai and serve sectors that deal with challenging weld environments, such as energy, marine, HVAC, and structural fabrication. If your project involves awkward angles, dissimilar metals, or special coatings, we can provide a suitable welding plan without compromising quality.

We work thoroughly to optimize the joint type, weld parameters, and sequence for best results. With a full suite of laser tools and auxiliary fixturing systems, we offer flexibility across various beam shapes, wall thicknesses, and material grades.

Supporting a Range of Materials and Profiles

Our welding process covers many materials including carbon steel, aluminum, and stainless steel. Each material requires different heat input, travel speed, and shielding gas strategies—which our team handles with expertise.

It might be aluminum laser welding in Dubai where control over heat input is very important, or stainless steel laser welding in Dubai where aesthetic and anti-corrosive finishes matter, Morshedi delivers precision tailored to purpose.

We also accommodate galvanized steel, brass, copper, and other alloys to provide defect-free welds with strong metallurgical bonding and minimal porosity.

Micro Laser Welding for High-Precision Tasks

For components that require tight tolerances or microscopic weld seams, we offer micro laser welding in Dubai. It can be best for fine medical instruments, electronic components, sensor assemblies, and intricate mechanical parts.

With beam sizes as small as 0.1 mm, we can perform welds invisible to the naked eye, without affecting nearby materials or components. Our micro welding ensures structural strength, repeatability, and visual cleanliness in every weld.

Machine Features:

- Capable of welding beams, structural tubes, sheet metal, and profiles.

- Advanced MIG and ARC welding for high-strength industrial applications.

- Supports negotiable thicknesses, depending on project requirements.

Materials & Profiles Welded

Mild Steel (MS), Stainless Steel (SS), Aluminum (AL), Galvanized Steel (GI)

I-Beam, U-Profile (Channel), L-Profile (Angle), T-Profile, Z-Profile

Pipe Profiles, Structural Tubes (Square & Rectangular), Hot & Cold Rolled Profiles

Applications of Laser Welding

Construction & Infrastructure

Welding structural beams and profiles for buildings.

Automotive & Aerospace

High-strength welding for vehicle frames and aircraft parts.

Industrial Fabrication

Precision welding for machinery and manufacturing.

Shipbuilding & Marine

Corrosion-resistant welding for marine applications.

Oil & Gas Industry

Welding pipelines and structural components for energy projects.

Our Laser Welding Process

Project Assessment & Material Selection

Reviewing welding needs based on material type.

Precision Welding

Using MIG-ARC laser technology for accurate, strong bonds.

Quality Inspection & Testing

Ensuring defect-free welds that meet industry standards.

Final Delivery & Assembly Support

Providing high-strength welded parts for industrial applications.

Contact Morshedi for the Best Laser Welding Services in Dubai

Looking for high-precision laser welding services in Dubai? Morshedi as a full-service laser welding contract manufacturer in Dubai specializes in strong, distortion-free laser welding for construction, automotive, and industrial applications.

You might be a multinational OEM or a local fabrication shop, if you choose Morshedi, it means you are choosing precision, accountability, and quality assurance. Our precision laser welding in Dubai are backed by trained professionals, in-house inspectors, and robust equipment calibrated for consistent output.

Frequently Askes Questions (FAQs)

1: What is laser welding and how does it work?

Laser welding is a technique that uses a fixated laser beam to fuse metals. It generates deep, clean welds with low amount of heat distortion. It is considered good for thin materials and complex assemblies.

3: Laser welding vs TIG/MIG: which is better?

Laser welding offers quicker processing, less heat input, and cleaner seams than TIG or MIG. It is better for exactness, while TIG/MIG can be good for manual or less difficult welding tasks.

5: What are the advantages of laser welding?

A very important benefit you can get with laser welding service is the precision. It make sure minimal distortion, clean welds, high speed, and compatibility with metals like aluminum, stainless steel, and galvanized steel.

7: Do laser welding providers offer quality assurance and customer service?

Yes, many laser welding providers offer strict quality control, review protocols, and customer service to make sure that all welds are done by following industry standards and client specifications.

2: Which welding is strongest?

Among all methods, laser welding can create some of the strongest and cleanest welds. It is mainly for fine or high-strength materials, due to its deep penetration and well-ordered heat application.

4: Are laser-welded signboards weather-resistant?

Yes, laser-welded signboards are highly weather-resistant. It provides corrosion-free joints and sturdy bonding that can withstand outdoor conditions that them faultless for long-term exterior applications.

6: What industries utilize laser welding?

Common industries laser welding supports include automotive, aerospace, electronics, medical devices, and construction. It is excellent for any sector requiring exact, sturdy, and capable metal joining.

8: What types of laser welding are commonly used in Dubai?

Laser welding types commonly used in Dubai include fiber laser welding, CO₂ laser welding, and hybrid welding. It depends on type of the material, scale of the project, and required joint strength.