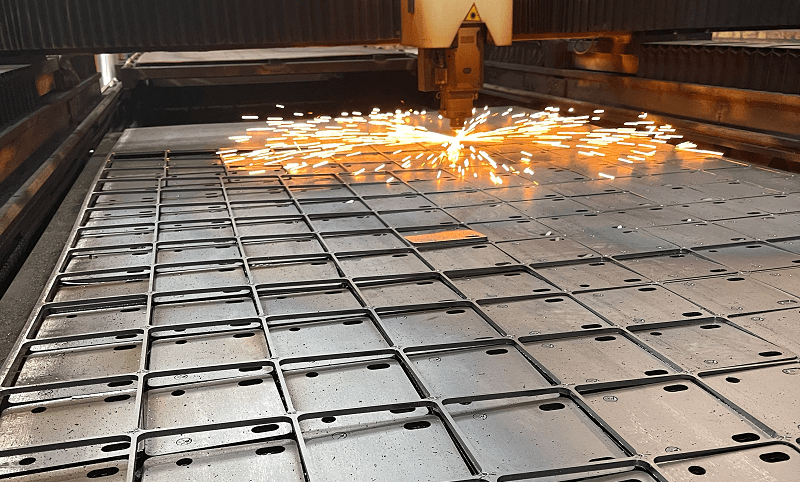

HVAC (Heating, Ventilation, and Air Conditioning) systems are essential for maintaining comfortable indoor environments in residential, commercial, and industrial settings. The ductwork that makes up these systems must be fabricated to precise specifications to ensure optimal performance and energy efficiency. Laser cutting is a cutting-edge technology that has revolutionized the way HVAC ductwork and related components are fabricated. In this post, we will examine the many benefits of laser cutting for HVAC and ductwork fabrication.

Precision and Accuracy

Laser cutting offers unparalleled precision and accuracy when fabricating HVAC ductwork and related components. The laser beam can be precisely controlled to cut even the most intricate shapes and designs with ease. This level of precision ensures that each component is fabricated to exact specifications, resulting in a perfect fit and optimal system performance. Additionally, laser cutting eliminates the need for secondary machining or finishing operations, saving time and reducing costs.

Speed and Efficiency

Laser cutting is a fast and efficient method for fabricating HVAC ductwork and related components. Unlike traditional methods such as manual cutting or plasma cutting, laser cutting can complete the fabrication process quickly and accurately, reducing lead times and increasing productivity. Additionally, laser cutting is a non-contact process, which means that there is minimal material distortion, resulting in less scrap and waste.

Flexibility

Laser cutting is highly flexible and can be used to fabricate a wide range of materials used in HVAC systems, including steel, aluminum, and various alloys. Additionally, laser cutting can be used to create complex shapes and designs, making it an ideal choice for custom ductwork and components.

Quality and Consistency

Laser cutting ensures high-quality and consistent results in each fabrication process. The precise control of the laser beam eliminates the risk of errors or mistakes, resulting in superior quality components that meet or exceed industry standards. Additionally, laser cutting is a repeatable process, ensuring that each component is fabricated to the same exact specifications, regardless of the batch size.

Cost-Effective

Laser cutting is a cost-effective method for fabricating HVAC ductwork and related components. The precision and efficiency of laser cutting result in less waste and scrap, reducing material costs. Additionally, laser cutting eliminates the need for secondary machining or finishing operations, further reducing costs and increasing productivity. The speed and efficiency of laser cutting also mean that lead times are reduced, allowing projects to be completed faster and with greater cost-effectiveness.

Conclusion

Laser cutting is a highly efficient and precise method for fabricating HVAC ductwork and related components. The numerous benefits of laser cutting, including precision, speed, flexibility, quality, consistency, and cost-effectiveness, make it an ideal choice for HVAC applications. By utilizing laser cutting technology, HVAC professionals can fabricate ductwork and related components quickly, accurately, and cost-effectively, resulting in optimal system performance and energy efficiency.